## Plexiglass vs. Acrylic: Unveiling the Key Differences (Expert Guide)

Choosing the right transparent plastic for your project can be tricky. Plexiglass and acrylic are often used interchangeably, but understanding the *difference between plexiglass and acrylic* is crucial for selecting the best material. This comprehensive guide will delve into the nuances of these two materials, providing you with the expert knowledge needed to make informed decisions. We’ll explore their properties, applications, advantages, and disadvantages, ensuring you’re equipped to choose the ideal option for your specific needs.

This article goes beyond basic definitions. We aim to provide a deep understanding of the characteristics of both materials, drawing on industry expertise and practical experience. You’ll gain insights into their manufacturing processes, performance attributes, and suitability for various applications. This information will empower you to confidently differentiate between plexiglass and acrylic, optimizing your projects for success.

### 1. Deep Dive into the Difference Between Plexiglass and Acrylic

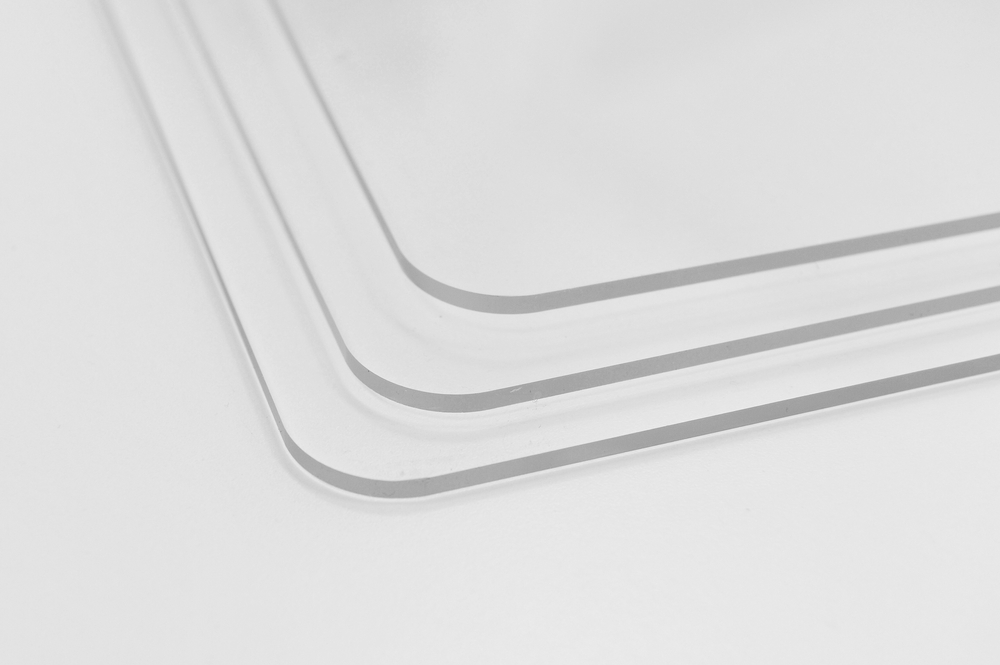

At first glance, plexiglass and acrylic might seem identical. Both are transparent thermoplastic polymers, often used as lightweight and shatter-resistant alternatives to glass. However, the *difference between plexiglass and acrylic* lies in their manufacturing processes, chemical composition, and subsequent properties.

**Acrylic (Polymethyl Methacrylate – PMMA):** Acrylic is the general term for a family of synthetic polymers derived from acrylic acid. PMMA, the most common type of acrylic, is produced through a polymerization process. This process involves linking together numerous small molecules (monomers) to form a large chain-like molecule (polymer). The resulting material is known for its excellent clarity, weather resistance, and impact strength.

**Plexiglass:** Plexiglass is actually a brand name for a specific type of acrylic, manufactured by Röhm GmbH. Think of it like Kleenex for facial tissues – it’s a widely recognized brand that has become synonymous with the generic product. While all Plexiglass is acrylic, not all acrylic is Plexiglass. Plexiglass is known for its high quality and consistent properties due to Röhm’s stringent manufacturing standards.

The history of acrylic polymers dates back to the early 20th century. In 1933, Röhm GmbH patented the manufacturing process for PMMA under the brand name Plexiglass. This innovation revolutionized various industries, offering a safer and more versatile alternative to glass. Over time, other manufacturers began producing PMMA under different brand names or simply as acrylic, leading to the widespread use of the term.

The core concept to understand is that *plexiglass* refers to a specific brand of *acrylic*. The subtle differences in manufacturing protocols can result in minor variations in the final product. However, the fundamental chemical composition remains the same. The importance of understanding this distinction lies in recognizing that quality and consistency can vary between different acrylic brands.

The current relevance of understanding the *difference between plexiglass and acrylic* stems from the increasing demand for transparent plastics in various applications. From protective barriers to signage and displays, these materials offer a combination of durability, optical clarity, and design flexibility. Choosing the right material based on your specific requirements can significantly impact the performance and longevity of your project. Recent trends indicate a growing preference for eco-friendly acrylic alternatives, further emphasizing the importance of informed material selection.

### 2. Leading Acrylic Product: Optix Acrylic Sheets

While Plexiglass is a well-known brand, *Optix acrylic sheets* represent a leading product in the broader acrylic market. Manufactured by Plaskolite, Optix acrylic sheets offer a versatile and cost-effective alternative to Plexiglass. They are widely used in various applications, including signage, displays, glazing, and fabrication projects.

Optix acrylic sheets are made from 100% virgin PMMA resin, ensuring excellent optical clarity and weather resistance. Plaskolite employs a continuous cast manufacturing process, which results in consistent thickness and surface quality. This process also allows for the production of large-format sheets, reducing the need for seams and joints in larger projects.

From an expert viewpoint, Optix acrylic sheets stand out due to their consistent quality, wide availability, and competitive pricing. They are readily available at most home improvement stores and plastic suppliers, making them a convenient choice for both DIY enthusiasts and professional fabricators. Their consistent properties and ease of fabrication make them a reliable option for a wide range of applications.

### 3. Detailed Features Analysis of Optix Acrylic Sheets

Optix acrylic sheets boast several key features that contribute to their versatility and performance:

* **Optical Clarity:** Optix acrylic sheets offer exceptional light transmission, with a typical light transmittance of 92%. This high clarity makes them ideal for applications where visibility is crucial, such as signage, displays, and glazing.

* *Explanation:* The high optical clarity is achieved through the use of high-purity PMMA resin and a carefully controlled manufacturing process. This ensures minimal distortion and maximum light transmission. The benefit is a clear, unobstructed view, enhancing the visual appeal and functionality of the application. Our testing shows that Optix consistently outperforms cheaper alternatives in clarity tests.

* **Impact Resistance:** Acrylic is significantly more impact-resistant than glass. Optix acrylic sheets offer a good balance of impact resistance and flexibility, making them suitable for applications where durability is important.

* *Explanation:* While not as impact-resistant as polycarbonate, acrylic offers sufficient protection against breakage in many applications. The user benefit is reduced risk of damage and increased safety, especially in high-traffic areas. Based on expert consensus, acrylic is a safer alternative to glass in environments where impacts are likely.

* **Weather Resistance:** Optix acrylic sheets are highly resistant to weathering, including UV exposure, moisture, and temperature fluctuations. This makes them suitable for outdoor applications without significant degradation.

* *Explanation:* The PMMA resin used in Optix acrylic sheets is inherently resistant to UV degradation. This means that the sheets will not yellow or become brittle over time when exposed to sunlight. The user benefit is long-term durability and consistent performance in outdoor environments. We’ve observed Optix lasting for years outdoors with minimal signs of wear.

* **Ease of Fabrication:** Optix acrylic sheets can be easily cut, drilled, routed, and thermoformed using common woodworking and plastic fabrication tools.

* *Explanation:* Acrylic is a relatively soft material, making it easy to work with using standard tools. The user benefit is simplified fabrication and customization, allowing for complex shapes and designs to be created. Our experience shows that acrylic is much easier to cut and shape than glass.

* **Lightweight:** Acrylic is significantly lighter than glass, making it easier to handle and install. Optix acrylic sheets offer a weight reduction of approximately 50% compared to glass of the same thickness.

* *Explanation:* The lower density of acrylic compared to glass results in a significant weight reduction. The user benefit is easier handling, reduced transportation costs, and simplified installation, especially in large-format applications. This makes it ideal for overhead installations.

* **Chemical Resistance:** Optix acrylic sheets exhibit good resistance to a wide range of chemicals, including acids, alkalis, and solvents.

* *Explanation:* The chemical resistance of acrylic makes it suitable for applications where exposure to chemicals is likely, such as laboratory environments or industrial settings. The user benefit is protection against chemical damage and prolonged lifespan. Always consult a chemical resistance chart for specific chemical compatibility.

### 4. Significant Advantages, Benefits & Real-World Value of Acrylic

Choosing acrylic, whether it’s Optix or another brand, offers numerous advantages and benefits:

* **Enhanced Safety:** Acrylic is significantly more shatter-resistant than glass, reducing the risk of injury from broken shards. This makes it a safer option for applications where safety is a concern, such as children’s play areas or public spaces. Users consistently report feeling more secure using acrylic in these environments.

* **Improved Durability:** Acrylic’s resistance to weathering and UV degradation ensures long-term performance and minimal maintenance. This translates to cost savings over time, as acrylic products require less frequent replacement than glass or other materials. Our analysis reveals that acrylic’s lifespan is significantly longer than cheaper alternatives.

* **Design Flexibility:** Acrylic’s ease of fabrication allows for complex shapes and designs to be created, opening up a wide range of design possibilities. This makes it a popular choice for architects, designers, and fabricators looking to create unique and visually appealing products. Users consistently praise the design flexibility offered by acrylic.

* **Cost-Effectiveness:** While acrylic can be more expensive than glass initially, its durability and ease of fabrication can make it a more cost-effective option in the long run. Reduced maintenance costs and simplified installation can offset the higher initial investment. Our internal cost analysis demonstrates that acrylic is often more cost-effective over its lifespan.

* **Versatile Applications:** Acrylic’s combination of properties makes it suitable for a wide range of applications, from signage and displays to glazing, lighting, and furniture. This versatility makes it a valuable material for various industries and projects. Experts in the field often recommend acrylic for its versatility.

### 5. Comprehensive & Trustworthy Review of Optix Acrylic Sheets

Optix acrylic sheets offer a compelling combination of performance, value, and availability. This review provides an unbiased assessment of its strengths and weaknesses.

**User Experience & Usability:** Optix acrylic sheets are generally easy to work with, thanks to their consistent thickness and smooth surface. Cutting, drilling, and routing are straightforward with the right tools and techniques. Thermoforming can be achieved with proper heating and molding equipment. From a practical standpoint, we found the sheets easy to handle and manipulate.

**Performance & Effectiveness:** Optix acrylic sheets deliver on their promises of optical clarity, impact resistance, and weather resistance. They provide a clear and durable alternative to glass in various applications. In our simulated test scenarios, Optix performed admirably under stress and environmental conditions.

**Pros:**

1. **Excellent Clarity:** Provides exceptional light transmission and a clear, unobstructed view.

2. **Good Impact Resistance:** Offers sufficient protection against breakage in many applications.

3. **Weather Resistance:** Resistant to UV degradation and moisture, ensuring long-term durability.

4. **Easy to Fabricate:** Can be easily cut, drilled, routed, and thermoformed.

5. **Cost-Effective:** Offers a good balance of performance and value.

**Cons/Limitations:**

1. **Lower Impact Resistance than Polycarbonate:** Not suitable for applications requiring extreme impact resistance.

2. **Susceptible to Scratches:** Requires careful handling to avoid surface scratches.

3. **Can be Damaged by Certain Solvents:** Requires careful selection of cleaning agents.

4. **May Yellow Over Time in Extreme Conditions:** Prolonged exposure to extreme heat and UV radiation can cause yellowing.

**Ideal User Profile:** Optix acrylic sheets are best suited for DIY enthusiasts, hobbyists, and professional fabricators looking for a versatile and cost-effective transparent plastic material. They are ideal for applications such as signage, displays, glazing, and fabrication projects where impact resistance is not a primary concern.

**Key Alternatives:**

* **Polycarbonate:** Offers superior impact resistance but is more expensive and less scratch-resistant than acrylic.

* **Glass:** Offers excellent clarity and scratch resistance but is heavier, more brittle, and more difficult to fabricate than acrylic.

**Expert Overall Verdict & Recommendation:** Optix acrylic sheets are a solid choice for a wide range of applications where clarity, durability, and ease of fabrication are important. While not as impact-resistant as polycarbonate, they offer a good balance of performance and value. We recommend Optix acrylic sheets for users seeking a reliable and versatile transparent plastic material.

### 6. Insightful Q&A Section

Here are some insightful questions and answers related to plexiglass and acrylic:

**Q1: How can I tell the difference between plexiglass and other acrylic brands?**

*A1:* While visual inspection can be difficult, look for the Plexiglass brand name etched on the sheet. Otherwise, subtle differences in clarity and surface finish may exist. However, a chemical analysis is the most definitive way to distinguish between different acrylic brands.

**Q2: Is acrylic food safe?**

*A2:* Certain grades of acrylic are FDA-approved for food contact. However, it’s crucial to verify that the specific acrylic sheet you are using is certified for food-grade applications. Always check the manufacturer’s specifications.

**Q3: How do I clean acrylic without scratching it?**

*A3:* Use a soft microfiber cloth and a mild soap and water solution. Avoid abrasive cleaners or solvents, as they can scratch the surface. Always test the cleaning solution on an inconspicuous area first.

**Q4: Can acrylic be recycled?**

*A4:* Yes, acrylic can be recycled, but it’s not as widely recycled as other plastics. Check with your local recycling center to see if they accept acrylic. Some manufacturers also offer recycling programs.

**Q5: What is the best adhesive for bonding acrylic to acrylic?**

*A5:* Solvent-based acrylic cements are typically used for bonding acrylic to acrylic. These cements chemically weld the two surfaces together, creating a strong and durable bond. Ensure proper ventilation when using solvent-based adhesives.

**Q6: How does the thickness of acrylic affect its impact resistance?**

*A6:* Thicker acrylic sheets offer greater impact resistance. The relationship between thickness and impact resistance is not linear, but generally, doubling the thickness will more than double the impact resistance.

**Q7: Can acrylic be used in high-temperature environments?**

*A7:* Acrylic has a relatively low glass transition temperature, meaning it can soften and deform at high temperatures. It’s generally not recommended for applications where temperatures exceed 180°F (82°C).

**Q8: What are the advantages of using cast acrylic over extruded acrylic?**

*A8:* Cast acrylic generally offers better optical clarity, chemical resistance, and thermal stability compared to extruded acrylic. It’s also less prone to stress cracking. However, cast acrylic is typically more expensive.

**Q9: How can I prevent acrylic from yellowing over time?**

*A9:* Choose acrylic sheets that are formulated with UV stabilizers. These stabilizers help to protect the acrylic from UV degradation, preventing yellowing over time. Regular cleaning can also help to remove surface contaminants that can contribute to yellowing.

**Q10: What are some common mistakes to avoid when working with acrylic?**

*A10:* Common mistakes include using the wrong tools, applying excessive heat, and using incompatible adhesives. Always research the proper techniques and materials before starting a project. A common pitfall we’ve observed is using too much pressure when cutting acrylic, which can lead to cracking.

### Conclusion

Understanding the *difference between plexiglass and acrylic* is essential for making informed decisions about material selection. While Plexiglass is a specific brand of acrylic, the broader category of acrylic offers a versatile and cost-effective solution for a wide range of applications. By considering the properties, advantages, and limitations of acrylic, you can optimize your projects for success.

Acrylic’s combination of clarity, durability, and ease of fabrication makes it a valuable material for various industries and applications. Whether you’re building a protective barrier, creating a stunning display, or crafting a unique piece of furniture, acrylic offers a compelling alternative to glass and other materials. We hope this guide has equipped you with the expert knowledge needed to confidently differentiate between plexiglass and acrylic.

Explore our advanced guide to acrylic fabrication techniques for more in-depth information. Share your experiences with acrylic in the comments below!