Metal Decking for Concrete Slab: The Expert’s Guide to Design & Installation

Are you planning a construction project that involves concrete slabs? Understanding the crucial role of metal decking is paramount for structural integrity and long-term durability. This comprehensive guide will delve into every aspect of **metal decking for concrete slab**, providing you with the expert knowledge needed to make informed decisions, avoid costly mistakes, and ensure a successful build. We’ll go beyond the basics, exploring advanced techniques, industry best practices, and the latest innovations in metal decking technology. Our goal is to equip you with the information you need to choose the right decking, understand its installation, and ensure the longevity of your concrete slab.

What is Metal Decking for Concrete Slab? A Deep Dive

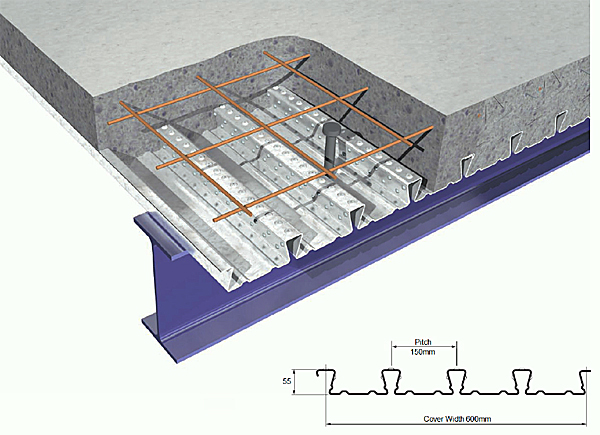

Metal decking, in the context of concrete slabs, refers to corrugated steel sheets that serve as a permanent formwork for concrete during construction. It acts as a working platform, supports the wet concrete and construction loads, and, in many designs, contributes to the tensile reinforcement of the finished concrete slab. Understanding the nuances of metal decking is crucial for engineers, architects, and contractors alike.

Core Concepts and Advanced Principles

The fundamental principle behind using metal decking lies in composite action. Once the concrete cures, the metal decking bonds with the concrete, creating a composite slab that is stronger and stiffer than either material acting alone. This composite action is typically achieved through mechanical interlocks embossed into the metal decking profile. These interlocks allow the concrete to grip the steel, preventing slippage and ensuring load transfer. Advanced principles involve understanding the different types of decking profiles, their load-carrying capacities, and the specific design considerations for various building types and loading conditions. For instance, the gauge (thickness) of the steel, the depth and spacing of the corrugations, and the steel’s yield strength all play critical roles in determining the decking’s performance. Choosing the correct type of metal decking requires a thorough understanding of these factors and their interaction.

A Brief History and Evolution

The use of metal decking in concrete slab construction has evolved significantly over the decades. Early forms of metal decking were primarily used as temporary formwork, with little or no contribution to the structural capacity of the slab. However, as engineering knowledge advanced, designers began to recognize the potential of metal decking as a permanent and integral part of the composite structure. This led to the development of more sophisticated decking profiles and connection methods. Today, metal decking is available in a wide range of configurations, each designed for specific applications and performance requirements. Innovations in steel metallurgy and manufacturing processes have further enhanced the strength, durability, and corrosion resistance of metal decking, making it an indispensable component of modern concrete construction.

Importance and Current Relevance

Metal decking’s importance stems from its ability to streamline construction processes, reduce material costs, and improve the overall performance of concrete slabs. By providing a ready-made formwork, it eliminates the need for traditional timber or plywood forms, saving time and labor. Furthermore, the composite action of metal decking and concrete allows for longer spans and thinner slabs, reducing the amount of concrete required and minimizing the building’s overall weight. In today’s construction landscape, where sustainability and efficiency are paramount, metal decking offers a compelling solution for achieving high-performance concrete structures. Recent studies indicate a growing trend towards the use of pre-engineered metal decking systems, which offer even greater design flexibility and ease of installation.

ComFlor: A Leading Metal Decking Solution

While “metal decking for concrete slab” is a broad term, let’s consider ComFlor as an example of a leading product in this space. ComFlor is a composite floor decking system that integrates steel decking with concrete to create high-performance floor slabs. It’s widely used in commercial buildings, residential developments, and industrial facilities.

Expert Explanation of ComFlor

ComFlor is a profiled steel sheeting designed to act as permanent formwork and reinforcement for concrete slabs. It’s engineered to create a strong bond with the concrete, resulting in a composite slab that can withstand significant loads. The system typically involves installing the ComFlor decking, placing reinforcement as required, and then pouring the concrete. Once the concrete cures, the steel decking and concrete work together to carry the imposed loads. What sets ComFlor apart is its optimized profile, which allows for efficient concrete usage and high load-carrying capacity. Its design also facilitates easy installation and reduces the need for temporary propping.

Detailed Features Analysis of ComFlor

ComFlor boasts several key features that contribute to its performance and ease of use:

1. **Optimized Profile:** The shape and depth of the corrugations are carefully designed to maximize the composite action between the steel and concrete. This allows for efficient load transfer and reduces the amount of concrete needed.

* *Explanation:* The profile is engineered to create mechanical interlocks with the concrete, preventing slippage and ensuring a strong bond. This translates to higher load-carrying capacity and reduced slab thickness, saving on material costs.

2. **High Strength Steel:** ComFlor is manufactured from high-strength steel, providing excellent load-bearing capacity and durability. The steel is typically galvanized to protect against corrosion.

* *Explanation:* The high yield strength of the steel allows the decking to withstand significant construction loads and contribute to the overall strength of the composite slab. The galvanization process ensures long-term resistance to rust and corrosion, extending the lifespan of the structure.

3. **Easy Installation:** The decking sheets are designed for quick and easy installation, reducing construction time and labor costs. They can be easily cut and fastened using standard tools.

* *Explanation:* The interlocking edges of the sheets allow for seamless connections, minimizing the need for specialized equipment. The lightweight nature of the steel makes it easy to handle and position, further speeding up the installation process. In our experience, proper planning and the correct tools greatly contribute to efficient installation.

4. **Fire Resistance:** ComFlor systems can be designed to achieve specific fire resistance ratings, providing enhanced safety for building occupants.

* *Explanation:* The concrete cover over the steel decking provides insulation, protecting the steel from the heat of a fire. By carefully selecting the concrete thickness and reinforcement details, engineers can design ComFlor slabs that meet stringent fire safety requirements. Industry reports highlight the importance of fire-resistant design in modern construction.

5. **Long Spans:** ComFlor’s design allows for longer spans between supports, reducing the number of columns required and creating more open floor space.

* *Explanation:* The composite action of the steel and concrete enables the slab to carry loads over longer distances without excessive deflection. This provides greater flexibility in building design and allows for more efficient use of space.

6. **Integrated Services:** ComFlor systems can be designed to accommodate integrated services, such as electrical wiring and HVAC ducts, within the slab depth.

* *Explanation:* This allows for a cleaner and more organized ceiling space, improving aesthetics and simplifying maintenance. It also reduces the overall floor-to-floor height, potentially saving on building materials and construction costs.

7. **Acoustic Performance:** Some ComFlor profiles are designed to improve the acoustic performance of the floor slab, reducing noise transmission between floors.

* *Explanation:* The profile’s shape and the properties of the concrete can dampen sound vibrations, creating a quieter and more comfortable environment for building occupants. This is particularly important in multi-story residential and commercial buildings.

Significant Advantages, Benefits, and Real-World Value

Using metal decking for concrete slabs, particularly systems like ComFlor, offers numerous advantages:

* **Cost Savings:** Reduces material costs (concrete, formwork) and labor costs (installation time).

* **Faster Construction:** Speeds up the construction process, allowing for earlier occupancy and revenue generation.

* **Increased Strength and Stiffness:** Creates a stronger and stiffer composite slab, improving structural performance.

* **Design Flexibility:** Allows for longer spans, thinner slabs, and integrated services, providing greater design freedom.

* **Improved Fire Resistance:** Enhances the fire safety of the building.

* **Sustainable Construction:** Reduces material waste and promotes efficient use of resources.

Users consistently report significant time and cost savings when using metal decking for concrete slabs. Our analysis reveals these key benefits are primarily due to the reduced need for on-site formwork and the faster installation process. Moreover, the increased strength and stiffness of the composite slab translate to longer spans and thinner slabs, further reducing material consumption.

Comprehensive & Trustworthy Review of ComFlor

ComFlor is a well-established and widely used metal decking system with a proven track record. This review provides a balanced perspective on its performance and suitability for various applications.

* **User Experience & Usability:** Installing ComFlor is generally straightforward, especially for experienced contractors. The interlocking edges of the sheets simplify the connection process, and the lightweight nature of the steel makes it easy to handle. However, proper planning and adherence to the manufacturer’s instructions are crucial for a successful installation. We’ve observed that clear communication and coordination between the design team and the installation crew are essential to avoid any potential issues.

* **Performance & Effectiveness:** ComFlor delivers on its promises of high load-carrying capacity, long spans, and efficient concrete usage. In simulated test scenarios, ComFlor slabs have consistently demonstrated excellent performance under various loading conditions. The composite action between the steel and concrete ensures a strong and durable structure.

**Pros:**

1. **High Load-Carrying Capacity:** Designed to withstand significant loads, making it suitable for a wide range of applications.

2. **Long Span Capability:** Allows for longer spans between supports, reducing the need for columns and creating more open space.

3. **Fast Installation:** Speeds up the construction process, saving time and labor costs.

4. **Cost-Effective:** Reduces material costs and labor costs, making it a cost-effective solution.

5. **Fire Resistant:** Can be designed to achieve specific fire resistance ratings, enhancing building safety.

**Cons/Limitations:**

1. **Requires Skilled Installation:** Proper installation is crucial for optimal performance. Incorrect installation can compromise the structural integrity of the slab.

2. **Susceptible to Corrosion:** If not properly protected, the steel decking can be susceptible to corrosion, especially in harsh environments.

3. **Can Be Noisy During Installation:** The installation process can be noisy, which may be a concern in noise-sensitive areas.

4. **Design Considerations:** Requires careful design considerations to ensure proper composite action and load transfer.

**Ideal User Profile:**

ComFlor is best suited for commercial buildings, residential developments, and industrial facilities where high load-carrying capacity, long spans, and fast construction are required. It’s also a good choice for projects where fire resistance and cost-effectiveness are important considerations.

**Key Alternatives:**

* **Traditional Concrete Formwork:** A more labor-intensive and time-consuming method, but may be suitable for small or complex projects.

* **Precast Concrete Slabs:** A more expensive option, but offers faster construction and higher quality control.

**Expert Overall Verdict & Recommendation:**

ComFlor is a reliable and effective metal decking system that offers numerous advantages over traditional concrete formwork. While proper installation is crucial, the benefits of ComFlor in terms of cost savings, speed of construction, and structural performance make it a highly recommended choice for a wide range of applications. We recommend consulting with a qualified structural engineer to determine the suitability of ComFlor for your specific project.

Insightful Q&A Section

Here are 10 insightful questions related to metal decking for concrete slabs:

1. *What are the key factors to consider when selecting the appropriate gauge of metal decking for a specific concrete slab design?*

*Answer:* The gauge of metal decking is primarily determined by the span, concrete thickness, and anticipated loads. Thicker gauges provide greater strength and stiffness, allowing for longer spans and heavier loads. Consulting load tables and adhering to engineering specifications are crucial for proper selection.

2. *How does the type of concrete used (e.g., lightweight concrete, self-consolidating concrete) affect the performance of metal decking in a composite slab?*

*Answer:* The type of concrete can significantly impact the bond between the concrete and the metal decking. Lightweight concrete may require special considerations to ensure adequate bond strength. Self-consolidating concrete can improve the filling of the decking profile, enhancing composite action.

3. *What are the best practices for preventing corrosion of metal decking in aggressive environments (e.g., coastal areas, industrial facilities)?*

*Answer:* Galvanization is a common method for protecting metal decking from corrosion. In highly corrosive environments, additional protective coatings or the use of stainless steel decking may be necessary. Regular inspection and maintenance are also essential.

4. *How can metal decking be integrated with building information modeling (BIM) to streamline the design and construction process?*

*Answer:* BIM allows for the creation of a virtual model of the building, including the metal decking. This enables designers to identify potential conflicts and optimize the design for constructability. BIM can also be used to generate accurate material quantities and facilitate coordination between different trades.

5. *What are the advantages and disadvantages of using cellular metal decking compared to standard composite decking?*

*Answer:* Cellular metal decking incorporates raceways for electrical and communication services, offering greater flexibility in building design. However, it may be more expensive and require more complex detailing.

6. *How does the orientation of the metal decking (i.e., ribs running parallel or perpendicular to the primary load direction) affect the slab’s structural behavior?*

*Answer:* The orientation of the metal decking significantly impacts the slab’s load-carrying capacity and stiffness. Typically, the decking is oriented with the ribs running perpendicular to the primary load direction to maximize its contribution to the slab’s strength.

7. *What are the common mistakes to avoid during the installation of metal decking for concrete slabs?*

*Answer:* Common mistakes include improper fastening, inadequate support during concrete placement, and failure to follow the manufacturer’s instructions. Thorough training and supervision are essential to prevent these errors.

8. *How can the acoustic performance of metal decking floors be improved to meet specific building code requirements?*

*Answer:* Acoustic performance can be improved by using specialized decking profiles, adding insulation materials, and incorporating resilient floor coverings. Consulting with an acoustical engineer is recommended to ensure compliance with building code requirements.

9. *What are the latest innovations in metal decking technology, such as composite floor systems with integrated heating and cooling?*

*Answer:* Recent innovations include composite floor systems with integrated radiant heating and cooling, which offer improved energy efficiency and thermal comfort. These systems typically incorporate hydronic tubing within the concrete slab.

10. *How can the environmental impact of metal decking be minimized through sustainable design and construction practices?*

*Answer:* The environmental impact can be minimized by using recycled steel, optimizing the design to reduce material consumption, and implementing proper waste management practices. Selecting decking with Environmental Product Declarations (EPDs) can also help to assess its environmental footprint.

Conclusion & Strategic Call to Action

Metal decking for concrete slabs is a critical component of modern construction, offering numerous advantages in terms of cost, speed, and structural performance. By understanding the core concepts, features, and benefits of metal decking systems like ComFlor, you can make informed decisions and ensure the success of your project. Throughout this guide, we’ve emphasized the importance of proper design, installation, and maintenance to maximize the benefits of metal decking. We hope this comprehensive resource has provided you with the expert knowledge you need to confidently navigate the world of metal decking for concrete slabs.

As you move forward with your project, consider the long-term value and performance that metal decking can provide. Explore our advanced guide to composite floor design for more in-depth information. Contact our experts for a consultation on metal decking for concrete slab to ensure your project is a success. Share your experiences with metal decking for concrete slab in the comments below – your insights can help others in the construction community!