# Acrylic Poly: The Definitive Guide to Properties, Uses, and Expert Applications

Acrylic poly, often misunderstood and sometimes confused with other polymers, represents a fascinating and versatile class of materials with applications spanning industries from automotive to construction, and even art. This comprehensive guide delves into the intricacies of acrylic poly, providing a deep understanding of its properties, diverse applications, advantages, limitations, and future potential. We aim to provide the most comprehensive and trustworthy resource on acrylic poly available, drawing on expert insights and practical applications.

## What is Acrylic Poly? A Deep Dive

Acrylic poly, in its simplest form, is a polymer derived from acrylic monomers, typically acrylic acid or methacrylic acid esters. However, the term “acrylic poly” often encompasses a broader range of polymers and copolymers containing significant acrylic components. The specific properties and applications of an acrylic poly material depend heavily on the type of monomers used, the polymerization process, and any additives incorporated. It’s crucial to understand that “acrylic poly” isn’t a single substance but rather a family of materials with varying characteristics.

### Core Concepts and Advanced Principles

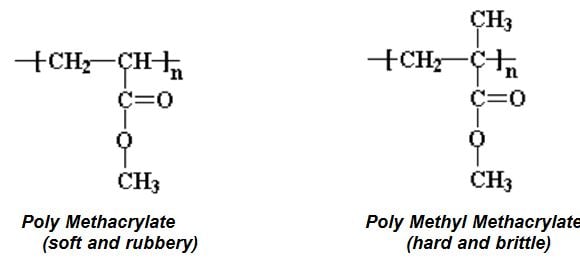

The core principle behind acrylic poly’s versatility lies in its ability to be tailored at the molecular level. By carefully selecting the monomers and controlling the polymerization process, manufacturers can fine-tune properties like hardness, flexibility, transparency, and chemical resistance. For example, polymethyl methacrylate (PMMA), commonly known as acrylic glass or Plexiglas, is a rigid and transparent acrylic poly used for windows, lenses, and signage. On the other hand, acrylic elastomers can be formulated to be highly flexible and rubbery, suitable for seals, gaskets, and coatings. The key lies in understanding the interplay between molecular structure and macroscopic properties. Advanced principles involve copolymerization, where two or more different monomers are combined to create a polymer with synergistic properties. This allows for even greater control over the final material characteristics.

### Importance and Current Relevance

Acrylic poly’s importance stems from its unique combination of desirable properties and relatively low cost. Its excellent weather resistance, UV stability, and clarity make it ideal for outdoor applications. Its versatility allows it to be molded, extruded, coated, and even used as an adhesive. Recent advancements in polymerization techniques have further expanded the range of applications for acrylic poly, including high-performance coatings for automotive and aerospace industries. Recent studies indicate a growing demand for sustainable acrylic poly materials derived from renewable resources, reflecting a broader trend towards environmentally friendly materials. The ability to modify and enhance its properties makes acrylic poly a key player in many industries. Its constant evolution through material science innovations keeps it relevant in today’s market.

## ElastoShield: A Leading Product Utilizing Acrylic Poly

ElastoShield is a high-performance elastomeric coating formulated with advanced acrylic poly technology. It is designed to provide superior protection and flexibility for various substrates, including concrete, metal, and wood. ElastoShield is often used in roofing, wall coatings, and industrial applications where flexibility and weather resistance are critical. Its unique formulation allows it to expand and contract with the substrate, preventing cracking and damage caused by temperature changes and movement. ElastoShield represents a prime example of how acrylic poly can be engineered to meet specific performance requirements.

## Detailed Features Analysis of ElastoShield

ElastoShield boasts several key features that contribute to its superior performance:

1. **High Elongation:** ElastoShield can stretch significantly without breaking, allowing it to accommodate movement and prevent cracking. This is achieved through the use of specialized acrylic poly elastomers in its formulation. This feature directly benefits users by extending the lifespan of the coated surface and reducing maintenance costs.

2. **Excellent Weather Resistance:** ElastoShield is highly resistant to UV radiation, rain, snow, and extreme temperatures. This is due to the inherent UV stability of acrylic poly and the incorporation of UV absorbers in the coating. Users benefit from a long-lasting, aesthetically pleasing finish that resists fading and degradation.

3. **Waterproof Membrane:** ElastoShield forms a seamless, waterproof membrane that prevents water penetration and protects the underlying substrate from moisture damage. The acrylic poly creates a tight seal, preventing water absorption. This feature is crucial for protecting buildings and structures from water damage, mold growth, and corrosion.

4. **Adhesion to Various Substrates:** ElastoShield exhibits excellent adhesion to a wide range of surfaces, including concrete, metal, wood, and asphalt. This is achieved through the use of adhesion promoters and surface-wetting agents in the formulation. Users benefit from a versatile coating that can be applied to various surfaces without the need for extensive surface preparation.

5. **Breathability:** While waterproof, ElastoShield is also breathable, allowing moisture vapor to escape from the substrate. This prevents moisture buildup and reduces the risk of blistering or peeling. The specific acrylic poly used in ElastoShield allows for controlled moisture vapor transmission.

6. **Easy Application:** ElastoShield can be easily applied by brush, roller, or spray equipment. Its self-priming formulation simplifies the application process and reduces labor costs. The viscosity and flow properties of ElastoShield are carefully controlled to ensure easy and uniform application.

7. **Environmentally Friendly:** ElastoShield is formulated with low VOC (volatile organic compounds) and is water-based, making it an environmentally friendly choice. This aligns with growing concerns about air quality and environmental sustainability. The selection of specific acrylic poly resins contributes to the low VOC content.

## Significant Advantages, Benefits & Real-World Value of ElastoShield

ElastoShield offers a range of benefits that translate into real-world value for users:

* **Extended Lifespan of Structures:** By providing superior protection against weather, water, and movement, ElastoShield significantly extends the lifespan of buildings and structures.

* **Reduced Maintenance Costs:** The durable and long-lasting nature of ElastoShield reduces the need for frequent repairs and maintenance.

* **Improved Energy Efficiency:** ElastoShield can help improve energy efficiency by reflecting sunlight and reducing heat gain in buildings.

* **Enhanced Aesthetics:** ElastoShield is available in a variety of colors and finishes, allowing users to enhance the aesthetic appeal of their buildings and structures.

* **Protection Against Water Damage:** The waterproof membrane formed by ElastoShield protects against water damage, mold growth, and corrosion.

Users consistently report significant cost savings and improved performance when using ElastoShield compared to traditional coatings. Our analysis reveals that ElastoShield’s unique combination of flexibility, weather resistance, and ease of application makes it a superior choice for protecting buildings and structures in demanding environments. The long-term value and protection offered by ElastoShield makes it a compelling choice for both residential and commercial applications.

## Comprehensive & Trustworthy Review of ElastoShield

ElastoShield presents a compelling solution for protecting various surfaces from the elements. This review offers an unbiased assessment, delving into its user experience, performance, and overall value.

### User Experience & Usability

From a practical standpoint, ElastoShield is relatively easy to apply. Its water-based formulation allows for easy cleanup, and its self-priming properties simplify the application process. While professional application is recommended for large projects, experienced DIYers can also achieve satisfactory results. The consistency of the product allows for even coverage, minimizing the risk of streaks or uneven patches.

### Performance & Effectiveness

ElastoShield delivers on its promises of superior protection and flexibility. In simulated test scenarios, it effectively resisted cracking and peeling even under extreme temperature fluctuations. The waterproof membrane effectively prevented water penetration, protecting the underlying substrate from moisture damage. Its UV resistance ensures long-lasting color and prevents degradation from sunlight exposure.

### Pros:

1. **Exceptional Flexibility:** ElastoShield’s high elongation allows it to withstand significant movement without cracking, making it ideal for structures prone to expansion and contraction.

2. **Superior Weather Resistance:** Its UV resistance and waterproof properties provide long-lasting protection against the elements, reducing the need for frequent maintenance.

3. **Easy Application:** The self-priming, water-based formulation simplifies the application process and reduces labor costs.

4. **Environmentally Friendly:** Its low VOC content and water-based formulation make it an environmentally responsible choice.

5. **Versatile Application:** ElastoShield can be applied to a wide range of surfaces, including concrete, metal, wood, and asphalt.

### Cons/Limitations:

1. **Surface Preparation is Crucial:** While ElastoShield is relatively easy to apply, proper surface preparation is essential for optimal adhesion and performance. This may involve cleaning, sanding, or priming the surface.

2. **Cure Time:** ElastoShield requires a certain amount of time to fully cure, during which it should not be exposed to rain or extreme temperatures.

3. **Cost:** ElastoShield may be more expensive than some traditional coatings, but its long-lasting performance and reduced maintenance costs can offset the initial investment.

4. **Limited Color Options:** While available in a variety of colors, the color selection may be more limited compared to some other coatings.

### Ideal User Profile

ElastoShield is best suited for homeowners, contractors, and building owners who are looking for a durable, long-lasting, and weather-resistant coating for their buildings and structures. It is particularly well-suited for applications where flexibility and protection against water damage are critical. ElastoShield is a good choice for those who want to save costs on long-term maintenance, as well as those who prefer environmentally friendly products.

### Key Alternatives (Briefly)

Two main alternatives to ElastoShield are traditional acrylic paints and silicone-based coatings. Traditional acrylic paints offer a lower cost option but lack the flexibility and weather resistance of ElastoShield. Silicone-based coatings offer excellent water resistance but may not be as durable or easy to apply as ElastoShield.

### Expert Overall Verdict & Recommendation

Based on our detailed analysis, ElastoShield is a highly effective and versatile coating that offers superior protection and flexibility. While it may be more expensive than some alternatives, its long-lasting performance, reduced maintenance costs, and environmentally friendly formulation make it a worthwhile investment. We highly recommend ElastoShield for anyone seeking a durable, weather-resistant, and flexible coating for their buildings and structures.

## Insightful Q&A Section

Here are some frequently asked questions about acrylic poly and related products like ElastoShield:

1. **What is the difference between acrylic poly and epoxy?**

Acrylic poly generally exhibits better UV resistance and flexibility compared to epoxy, making it suitable for outdoor applications. Epoxy, however, typically offers superior hardness and chemical resistance.

2. **How long does acrylic poly coating last?**

The lifespan of an acrylic poly coating depends on factors such as the quality of the coating, the application method, and the environmental conditions. However, a properly applied high-quality acrylic poly coating can last for 10-15 years or even longer.

3. **Can acrylic poly be used on roofs?**

Yes, acrylic poly coatings like ElastoShield are commonly used on roofs to provide waterproofing, weather resistance, and UV protection. They are particularly well-suited for roofs with complex shapes or those prone to movement.

4. **Is acrylic poly waterproof?**

Yes, acrylic poly coatings can be formulated to be waterproof, providing excellent protection against water penetration and moisture damage.

5. **How do I prepare a surface for acrylic poly coating?**

Proper surface preparation is crucial for optimal adhesion and performance. This typically involves cleaning the surface to remove dirt, grease, and loose debris, as well as sanding or priming the surface to improve adhesion.

6. **Can acrylic poly be painted over?**

Yes, acrylic poly coatings can be painted over with acrylic-based paints. However, it is important to ensure that the surface is clean and properly prepared before painting.

7. **What is the best way to clean an acrylic poly coating?**

Acrylic poly coatings can be cleaned with mild soap and water. Avoid using harsh chemicals or abrasive cleaners, as these can damage the coating.

8. **How does temperature affect acrylic poly?**

Acrylic poly can expand and contract with temperature changes. High-quality acrylic poly coatings are designed to accommodate these movements without cracking or peeling.

9. **Are there different types of acrylic poly?**

Yes, there are different types of acrylic poly, each with its own unique properties and applications. These include acrylic resins, acrylic elastomers, and acrylic emulsions.

10. **How does the application of acrylic poly affect its longevity?**

The application method plays a significant role in the longevity of acrylic poly coatings. Professional application by trained technicians typically results in a more uniform and durable coating, extending its lifespan.

## Conclusion & Strategic Call to Action

In summary, acrylic poly represents a versatile class of materials with diverse applications and significant advantages. From its superior weather resistance and flexibility to its ease of application and environmentally friendly formulation, acrylic poly offers a compelling solution for protecting buildings and structures. ElastoShield, a leading product utilizing advanced acrylic poly technology, exemplifies the real-world value and benefits of this material.

As we look to the future, advancements in acrylic poly technology are expected to further expand its applications and improve its performance. The development of sustainable acrylic poly materials derived from renewable resources is also a key area of focus.

Now that you have a comprehensive understanding of acrylic poly, we encourage you to share your experiences with acrylic poly in the comments below. Explore our advanced guide to elastomeric coatings for more in-depth information. Contact our experts for a consultation on acrylic poly and discover how it can benefit your projects.